With Scarce knowledge available on Hypermill we basically thought we were taking a chance if we purchased it.hyperMILL is a modular and versatile CAM solution for 2.4, 5 axes and 3D, as well as for milling and operations such as high-speed cutting (HSC), high-performance cutting (HPC) that are all embedded in one interface.The company behind hyperMILL is OPEN MIND Technologies AG, a German company with 100 percent holding of Mensch und Maschine SE (also a German company). We werent convinced that the support was there. 1.hyperMILL ADDITIVE Manufacturing opens up an array of flexible options for Directed Energy Deposition processes (DED) and Wire Arc Additive Manufacturing (WAAM).Give us a background about your flagship hyperMILL CAM/CAD software.The issue with Hypermill was the company who was selling it to us in our area really couldn't show us why Hypermill was better than Mastercam. Compare features, ratings, user reviews, pricing, and more from hyperMILL competitors and alternatives in order to make an informed decision for your business. SourceForge ranks the best alternatives to hyperMILL in 2021. Compare hyperMILL alternatives for your business or organization using the curated list below.

The turbine industry for power plants and the aerospace market and specific mold and die segments like the tyre mold industry.What are the various industry sectors where hyperMILL can be used? What are its different applications?We are covering most of the industry segments. Using our patented technology we created a sophisticated set of special application for various market segments, e.g. Due to very intense challenges in the CNC market we developed dedicated and very strong CAM solutions for the combined applications in MillTurn machines also.

Our main advantages are the possibility to react very quickly – with no loss of precision and quality, because hyperMILL offers powerful CAM strategies and supports CAM changes very fast. Very famous applications are turbine wheels and rotors, blades, bladed disks, shrouds, impellers and orthopedic implants.How useful is hyperMILL when creating prototypes?Prototyping is an ongoing process and it is a very tedious job involving manpower and a lot of man hours. Engine and structural parts as well as landing gears in aerospace, complex mold and die machining for tool rooms and automotive industry, R&D areas, prototyping.

Tire Mold Package is a special tailor made package and uses unique 5 axes dynamic roughing strategies.HyperMILL millTURN CAM software: The module is completely integrated in hyperMILLThe aerospace industry requires critical components that are often complex and difficult to machine. Our current installed versions with latest features are far ahead with any of our competitions and innovations still going on, for e.g. This is due to the fact that any user will not be fully utilising all the features in the CAM software and when needed we offer our online support or at site support to solve these issues or upgrades.Most of our users are already informed online if any up gradations are available or needs to be done.

There is high degree of complexity when we do rough machining and then the part goes for any external treatment and once again put back on the CNC machine. Aluminium alloys, special steels, Titanium Inconel, high temperature resistant materials and composites are already being machined for many years and many users have adopted conventional methods to machine them. These materials are tougher, lighter and have a very good durability. What role can hyperMILL play in this scenario?Indeed, this industry is very challenging.

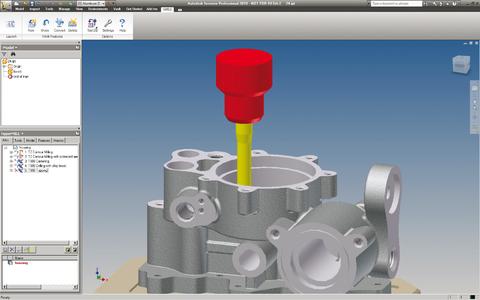

Many customers and tool rooms utilise only the 3D strategy for these applications. How do your CAM systems serve these objectives?Die and Mold industry of today and especially in India is demanding in terms of quick deliveries, quality, and cost. That´s why hyperMILL plays an important role in the aerospace industry.Die and mold industry’s success is determined by efficiency, cost-effectiveness and quality of mass production. Safety becomes utmost priority and hyperMILL has a very distinct advantage in this area by way of integrating Virtual Machining.We provide well known and proven cutting strategies to achieve consistent quality. HyperMILL takes its advantage by using very innovative strategies right from roughing, semi finishing, and final finishing, to cite a few cycles like, 5 axes arbitrary roughing and finishing, rest material removal, production mode, 5 axes drilling, 3D probing, automatic rest machining, and finally collision avoidance plays a very major role as the 5axes CNC milling machine also has some limitations in simultaneous movements.

To support all the above factors we employ specific strategies like high performance cutting, e.g: hyperMAXX in simultaneous 5 axes roughing and finishing. The machine employs high performance cutters, and other consumables to achieve the best results. Then follow semi finishing and finishing operations. Let me give you an example: starting to machine from a big block of steel, there is a lot of material removal, in fact the costly CNC machine merely becomes a chip making machine. The number of dies and molds are increasing and the 5 axis technology is already in production modes in various big and small tool rooms, (commercial tool rooms also).HyperMILL CAM strategies are designed to meet these demands. Whereas if you see globally in Europe, US, and China, Japan, they use 5 axes milling machines of different configurations and utilise very effective strategies to achieve economy in terms of mass production of dies or molds and not forgetting quality.We see a big benefit for Indian companies in the area of 5 axes methodology with Machine and CAM software to get best results.

As we also develop the postprocessor technology, hyperMILL comes with an all-in-one PP including 2D, 3D and 5 axis machining which requires no manual editing. The CAM system offers the ability to program the latest machining technology within an easy-to-use user interface. Air cutter movements are reduced. It offers a patented, automatic collision avoidance technology to make machining safer, better and faster – e.g. HyperMAXX is suitable for the machining of both hard and soft materials.It addresses the most important issues of the manufacturing area: hyperMILL significantly reduces programming time of high-quality NC programs. This enables highly efficient material removal with high process stability, thereby reducing machining times significantly.

To machine a family of parts with just a few clicks.One of OPEN MIND’s unique methods to drive automation processes is the “CPF” (= Customised Process Feature) that allows the user to identify repeated geometric components and to apply predefined manufacturing sequences for it. After the automation, the user can produce perfect NC programs for e.g. The results are always outstanding and very persuading. World-wide known companies, like Volkswagen, Fiat and Embraer, rely on our intelligent automation solutions.

0 kommentar(er)

0 kommentar(er)